Description

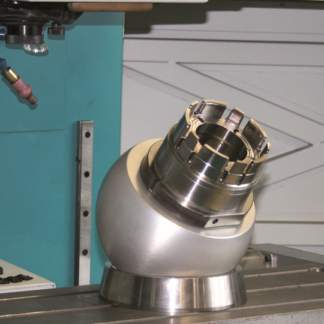

Typical set up procedure:

1) Switch ON up to 10–20% power

2) Workpiece centring

3) Switch ON up to 100% power

4) Workpiece machining

Construction

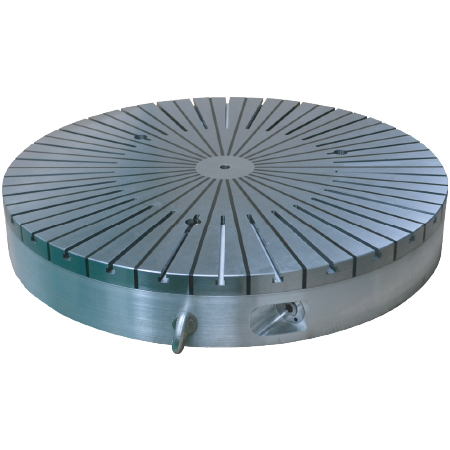

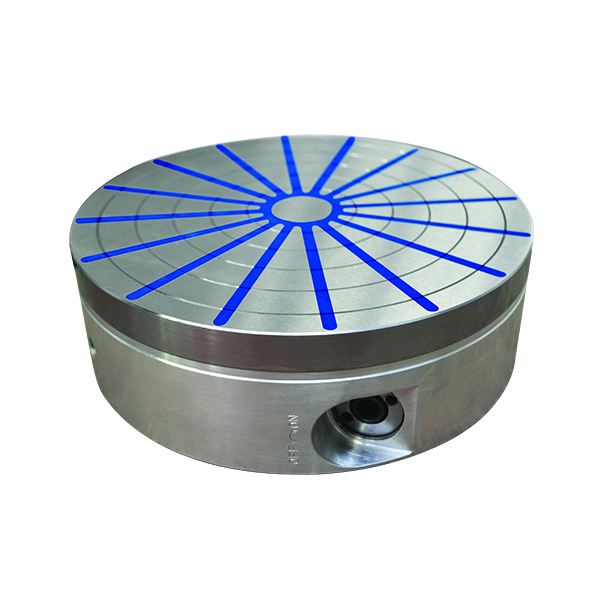

Robust, single piece top plate with radial poles and epoxy resin gaps

Double, high energy Neodymium magnetic system

Solid aluminium body with worm gear actuating mechanism, unique, very safe, self-locking mechanism, preventing switching-off during machining

Maximum clamping force up to 140 N/cm2 depending on the size of the chuck and the component

Application

Turning and grinding of ring shaped components

Scope of supply

Ratchet key

Options

Through going centre bore

Accurate centring hole

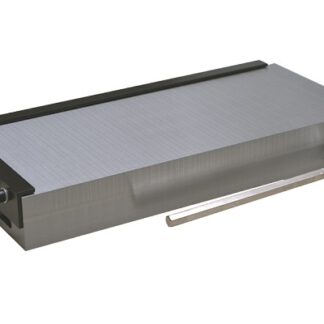

Auxiliary top plate

Top plate with T-slots

Set of pole shoes

Mounting of chuck to machine

The underside of the body has a recess and threaded holes for mounting a suitable flange.