Description

The vacuum revolution!

Do you think that vacuum lifts are only designed to handle smooth, clearly defined materials? The VUSS vacuum grippers from Aero-lift prove otherwise.

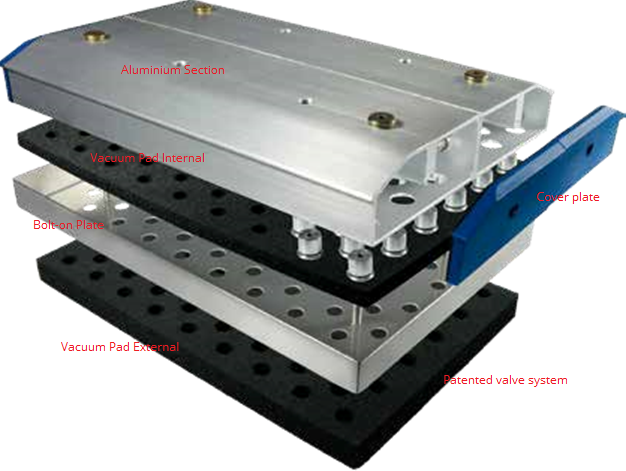

The latest generation of vacuum gripper with the patented vacuum valve system also allows for handling various goods or wooden elements with cut-outs or recesses without requiring any changeover.

The wood processing industry has been using vacuum lifting systems for many years to handle materials ranging from raw

materials to the end products. The vacuum plates with the unique flow valves pose very flexible solutions for the wood

processing industry. The vacuum systems are used both for handling un-machined materials like boards and/or planks as well as finished pieces of furniture – unpacked or packed in cartons

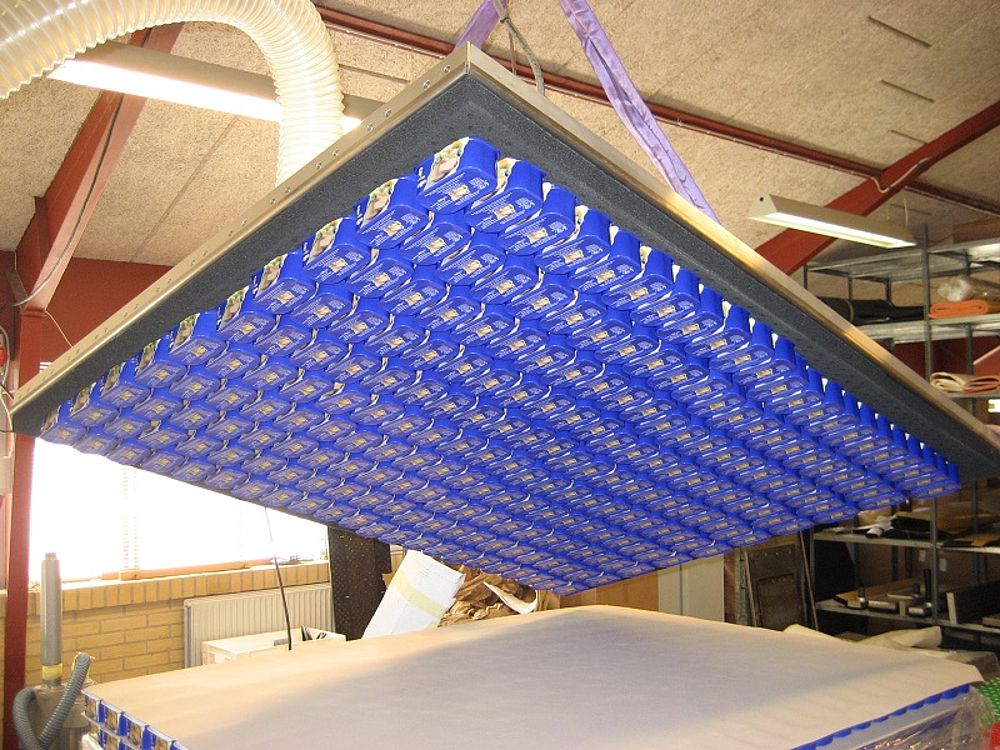

The basic principle is simple. The robot attached the vacuum plate to the product to be transported instead of grabbing it.

In such cases, robots do not have to recognise whether the products are holes, are slanted or comprise several parts.

With the Aero-lift Vuss, which uses flow control valves to activate and deactivate many small suction points, a vacuum is generated and the goods are moved safely in a fully automated manner to their destination.

This allows you to move large quantities of materials of various lengths and shapes quickly and cleanly, thus saving you a lot of time when it comes to logistics and the loading of equipment or the automated stacking of materials in the panel form. Be it for automated operation, flange-mounted onto the robots arm or manually controlled at the tube lifter, the VUSS vacuum grippers provide reliability, flexibility and effectiveness for your application.

The vacuum grippers are ready to work even in dirty environments where the products to be moved are coated with sawdust and dust