Description

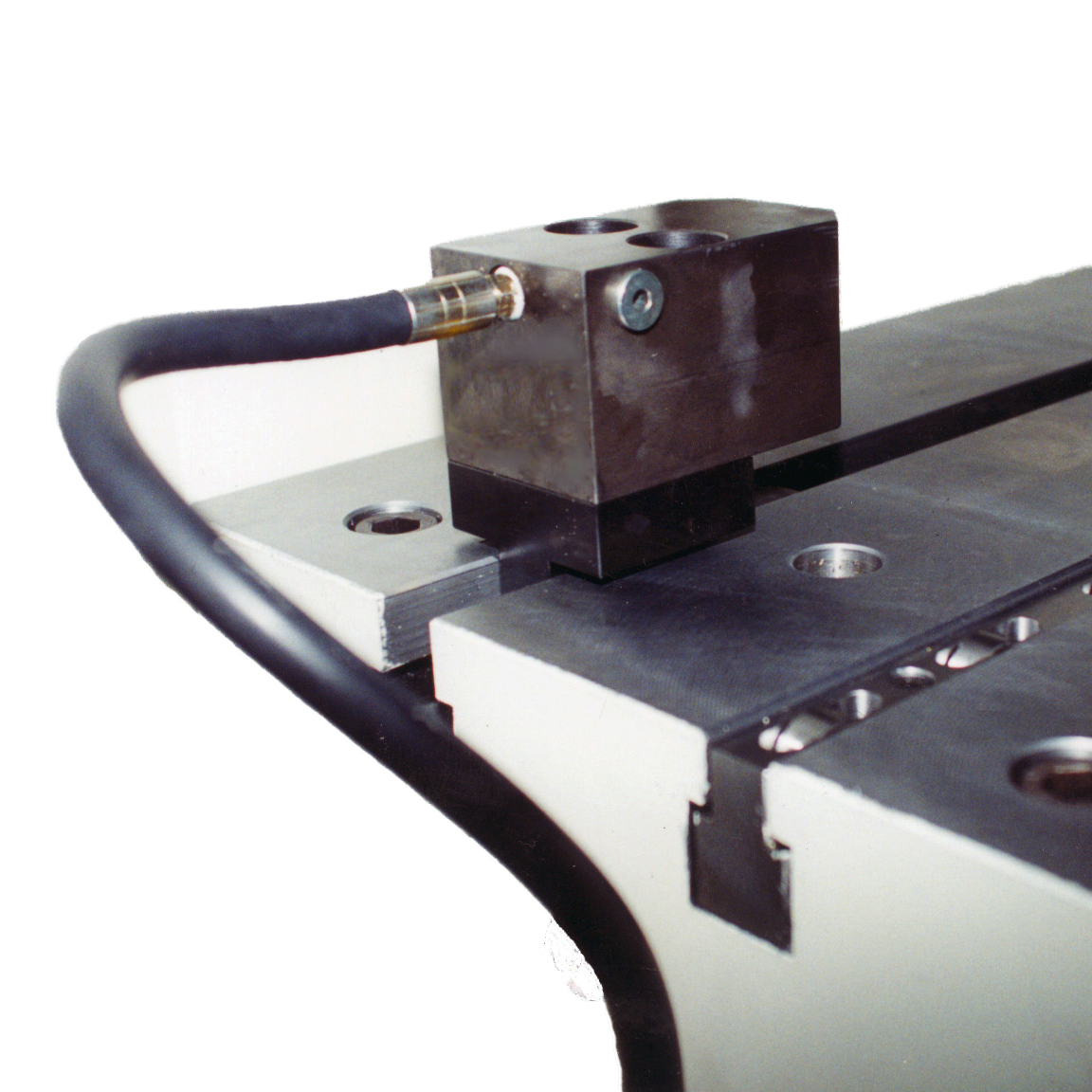

The single acting hydraulic MTC clamps can be used on non-standardized die back-plates. What sets apart the MTC T-slot clamp from the MHC & ECA is that the latter requires a slot on the die for positioning.

The MTC can be moved manually towards the die in the T-slot as the cylinders are equipped with T-stone sliding in the T-slot.

The single acting hydraulic T-slot clamps MTC are widely used on QDC applications.

Available with clamping forces 15, 30, 45 and 70 kN at 350 bar (5000 psi) and with a clamping stroke of 8 mm and the largest model 12 mm.

Suitable for 200°C as the cylinders are standard equipped with Viton seal.

MTC KEY POINTS

– Single acting hydraulic die clamp

– Suitable for non-standardized die back-plates

– Easy movable in T-slot

– Suitable for max 200°C

FUNCTION

MTC cylinders feature one oil connection to deliver hydraulic power in one direction. Once put under pressure, the cylinder “pushes” the piston against the die, clamping it. The integrated spring brings the piston back in its original unclamped position if the clamping pressure is taken away. The MTC clamps are moved manually towards the die in the T-slot. Because of the larger clamping stroke, these cylinders can be used for different sizes of back-plate thicknesses.

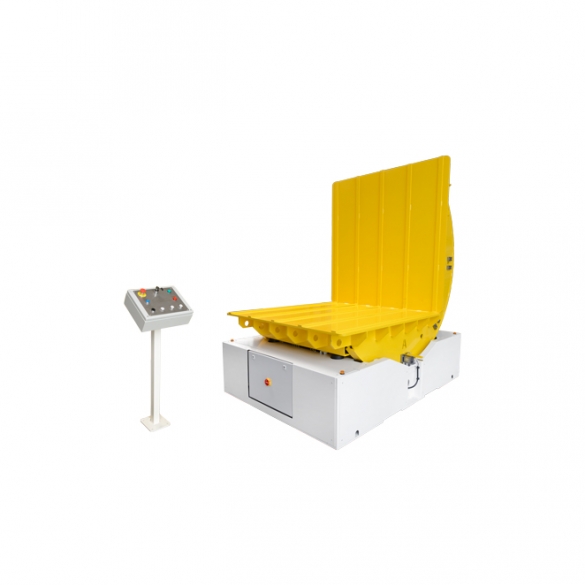

Application of the MTC T-slot clamps

On typical QDC applications with non-standardized back-plates 4 (or more) of these clamps are applied on the moving slide of the press and 4 (or more) on the bolster. For safety reasons the cylinders on the slide are connected to nr. 2 hydraulic circuits while on the bolster all cylinders are usually connected to nr. 1 hydraulic circuit. Alternatively it is possible to use only 1 hydraulic circuit on the slide side as well, then doubling the circuit with the use of the EAS double check valve EDCV-1, mounted on the slide.