Description

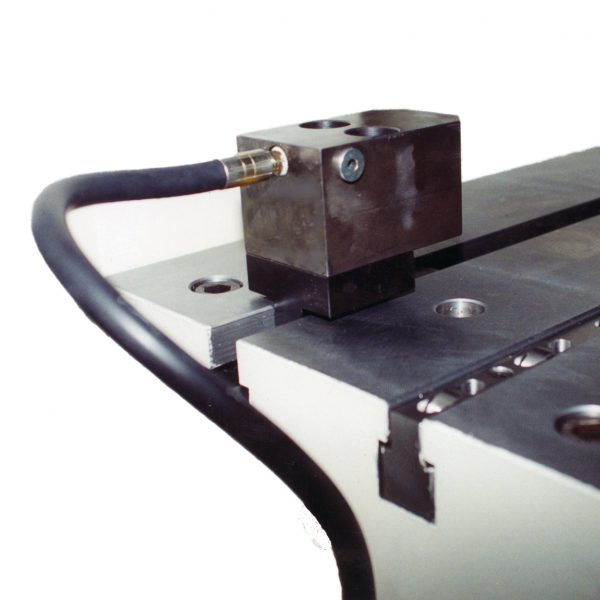

These clamping cylinders are a safe, quick and simple way to clamp dies or work pieces on (vertical) presses. The ECA single acting pull clamp is a low pricing, cost-effective clamping system, ideal for restricted areas.

The ECA clamps are easy installed and also suitable for retrofitting. A large range of clamping force, with a durable and compact design. There is hardly any distortion.

Pull cylinders for metal stamping presses hold down and lock the die back plate. For easy, safe clamping at points that can be difficult to reach, EAS offers two types of

T-slot pull cylinders for metal stamping presses:

ECA vs. MHC

Both series are simple means to improve productivity and reduce downtime. If more continuous pressure is required, the double acting cylinder series MOD, MPR or the swing clamp series MSR are recommended.

For standard QDC operations, opt for the ECA clamps. The ECA has a wider temperature range than the MHC, as well as bigger capacities when it comes to clamping force. For more heavy duty operations, the MHC pull clamp cylinders are a beter option. Both pull clamps are moved manually towards the die in the T-slot. Because of the large clamping stroke these cylinders can be used for different sizes of back-plate thicknesses.

APPLICATION

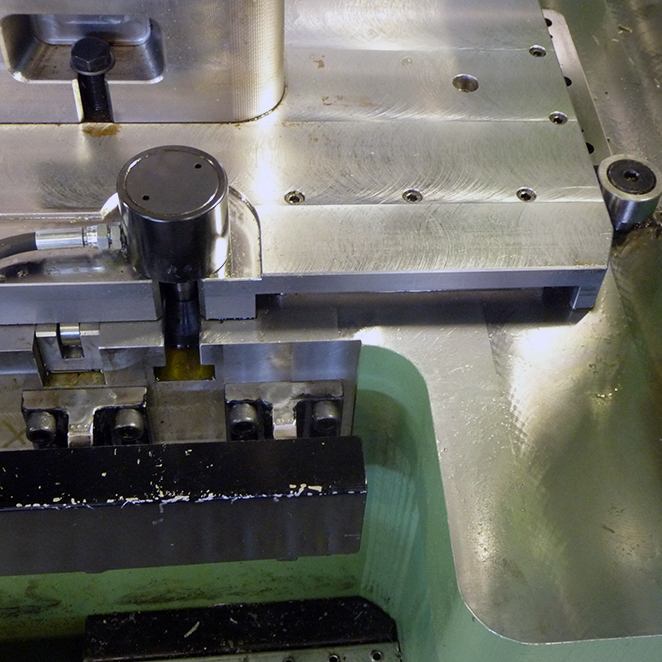

The ECA clamps are moved manually towards the die in the T-slot. On typical QDC applications with non-standardized back-plates four of these clamps are applied on the moving slide of the press, while four clamps function on the bolster.

Then the cylinders on the slide are connected to two single acting hydraulic circuits, all four clamps on the bolster connect to one hydraulic circuit.

The air hydraulic EAS pump units are very suitable to work with these single acting hydraulic clamps, also combined with hydraulic or air operated die lifters.

PSL Parking stations are available for orderly tuck away and protect the lifespan of the ECA and MHC pull clamp cylinders